Nowadays, you’ll be more likely to buy some branded jeans that cuffs are finished with colorful edged lines, which possess delicacy and personality. The deep black shades and red selvage detailing of Edwin’s ED-80 jeans, the unfussy and easy to wear skinny APC jeans, and the first-class quality of Levi’s 501 styles are extraordinary examples of significant benchmarks in the denim brand industry.

Why Does Selvedge Denim Come Back?

Although selvage denim is regarded as less-efficient, old-school, it never stops jeans-obsessed artisans from admiring it as a marker of higher-end denim at all. In their minds, a good pair of selvage jeans are hard to beat. Fast fashion dominates our dress-up, which ultimately lacks curated crafts in the current practical society. What’s more, people can often lose themselves in daily dress-up. The rising comeback of selvage denim jeans meets people’s demand of initial and simple wearing attitude and keeps their personality.

What Is Selvedge Denim?

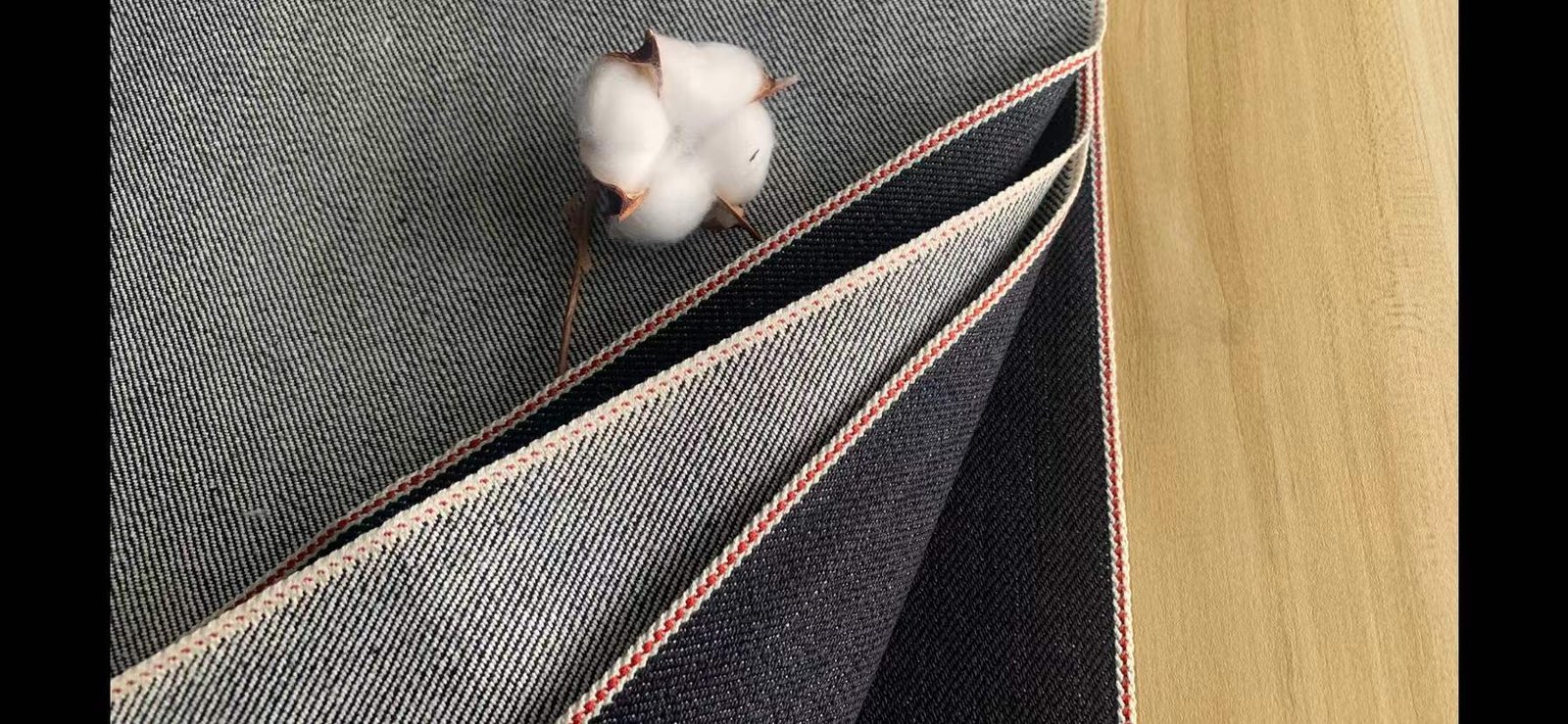

The word ‘selvage’ is a contraction of the words’ self-edge,’ representing the self-finished edges made on the denim prepared on shuttled looms. These shuttle looms weave a narrower 30-inch (finished) or 35-inch (raw) fabric, which is on average half the width of modern projectile looms. A considerable benefit of this denim is that the edges remain unraveled and do not fray. These edges are visible during the cuffing of jeans. One can see a white selvage ID and a colorful (usually red) but typically red yarn in the middle. Selvage denim is challenging to create and retains its reputation for being high-quality denim for that reason. Selvedge Denim also does not need to be washed as often as other kinds of denim.

Difference Between Selvedge Denim And Non-selvedge Denim

There are two methods for weaving denim: with or without a Shuttle. Weaving with a shuttle is the old-fashioned way. Is the shuttle the essential part? Yes, it holds the weft yarns, and it is shot from one side of the loom to the other, threading the weft yarns through the warp yarns. As the weft is a continuous piece of string, shooting backward and forwards, and the warp is changing and shifting, it seals both edges and makes a self-edge.

Flinging a shuttle to and from is a tedious cycle that makes bottlenecks for speedy production. Denim creation uses shuttle-less weaving machines based on the projectile look when manufacturers need to weave quicker and cheaper. They do this by replacing the shuttle entirely. Instead of the shuttle, there are multiple smaller projectiles like metallic bullets used to rock. These smaller projectiles carry the weft across the shed creating frayed edges at both sides of the fabric, which require cutting before being stitched into jeans pairs.

Shuttle-less weaving means that it leaves an unfinished edge. Whatever it needs, a lock stitch runs across this unfinished edge to stop unraveling, and this is precisely the kind of stitch you’re going to see in non-selvage jeans, and that is what makes denim either selvage or non-selvage.

Difference Between Raw Denim And Selvedge Denim

Raw denim is not necessarily selvage denim, and selvage denim by no means is always raw denim.

Raw denim is a rough and tough original denim fabric that is just finished from the manufacturing process. It is stiff and rigid as it has not been pre-soaked, washed, and enzyme desized(size means a kind of starch left on the cloth) in the water.

Selvage refers to the edge on the denim, as there is a unique unraveled edge in different colors when a shuttle loom works by passing thread horizontally over the regular vertical lines.

To reflect stylistic details of one selvage denim jeans, people wear them without pre-washing. However, the practice gradually changes when people can’t bear the weirdly stiff, like wearing two plaster casts on the legs.

Why Is Selvedge Denim More Expensive?

The projectile looms usually weave four times faster than the shuttle looms. In addition, production capacity is also increased ten times per hour because of the widening of the frame, causing a remarkable price shift. There is also a significant price difference between selvage and non-selvage denim due to the care and maintenance required for running old-fashioned shuttle looms.

Is Selvedge Denim Better?

Industry experts conclude that selvage denim blurs ‘better’ than non-selvage denim. The more slow speed of shuttle looms puts less pressure on the yarn. Also, shuttle looms endure more slubs in the thread, adding character to the denim. Yet the way that denim is selvage doesn’t essentially mean it is superior.

Since most selvage denim pants are not washed in a processing plant, they would likely endure a little longer in principle. But, when you don’t clean your raw denim pieces of garments, they’re not going to last as they could, assuming you washed them.

Usually, cheap types of denim are made from open-end and carded yarn, which is not as durable as ring-spun yarn, bringing about more defects on the fabric surface and hard hand feeling. While Ring-spun and combed yarn result in much more robust, neater, and softer features.

Hence, “selvage” is not an indicator of quality. Instead, just a style preference you’d like to cuff your jeans.

To cut a long story short, the saying “selvage denim is better than non-selvage” gets a little muddy when the material fiber is concerned.

How To Identify Well-made Selvedge Denim Jeans?

Indeed, we concentrate a lot on selvage denim fabric itself, but let’s also evaluate the quality of premium denim jeans as the material has to achieve its final mission.

The sewing on a well-prepared pair of raw selvage pants should be straight and tight. The hardware must feel unbeaten. Also, the stressed regions around the pockets and the crotch must be durable and last a long time. The wearing and washing of jeans make their finishing process complete, and it is done by sanforizing the pairs, so you do not have to go through the hassle of washing jeans any longer.

The pocket bags, the arcuate, the lined back pockets are invested inside and outside with care. The detailed work assures the lather patches, perfect stitching, seams, and hidden rivets. The more these fundamental points of quality and difference you notice, the better.

In summary, today’s market lacks charming fades’ texture, irregularities, and unevenness. The denim heads directly come to the denim ID by rolling cuffs to examine whether true

artisans have made these. Well-made raw selvage jeans are essential because of their adaptability and timeless quality. They are made to last, and they’ll never go out of fashion.

Where Can You Purchase The Selvedge Denim For Your Brands?

Since the American giant Cone mill White Oak plant shut down in December 2017, many reputed and esteemed mills are primarily distributed in Japan and Italy. (Japan-like Kuroki mills, Japan Blue/Collect mills, Nihon Menpu mills, and Kurabo mills in Okayama and Italy-like Candiani mills and Berto mills.) However, if your brand needs high-quality denim at a low budget and starts up your business fast, I highly recommend implementing your purchase in China like our mill.